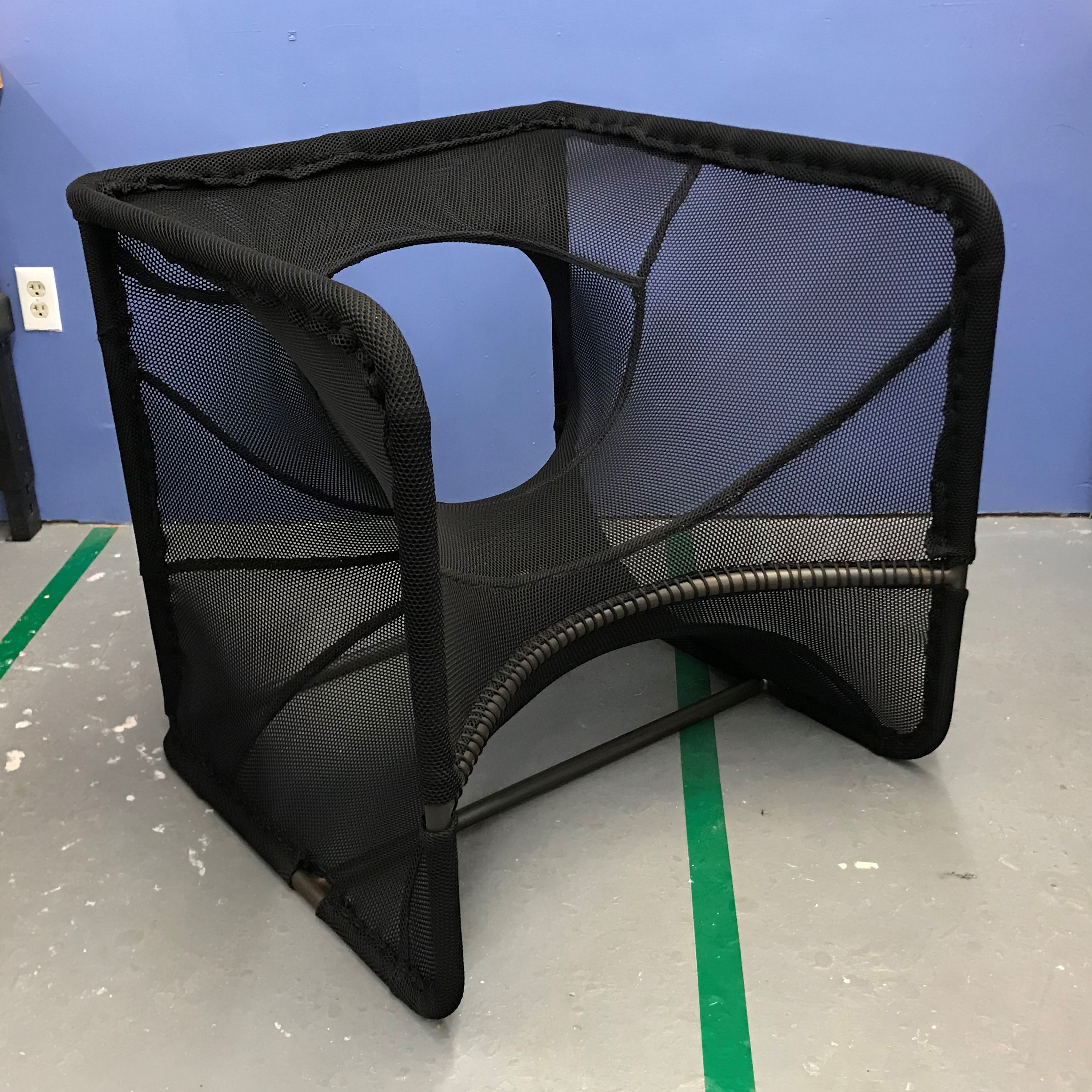

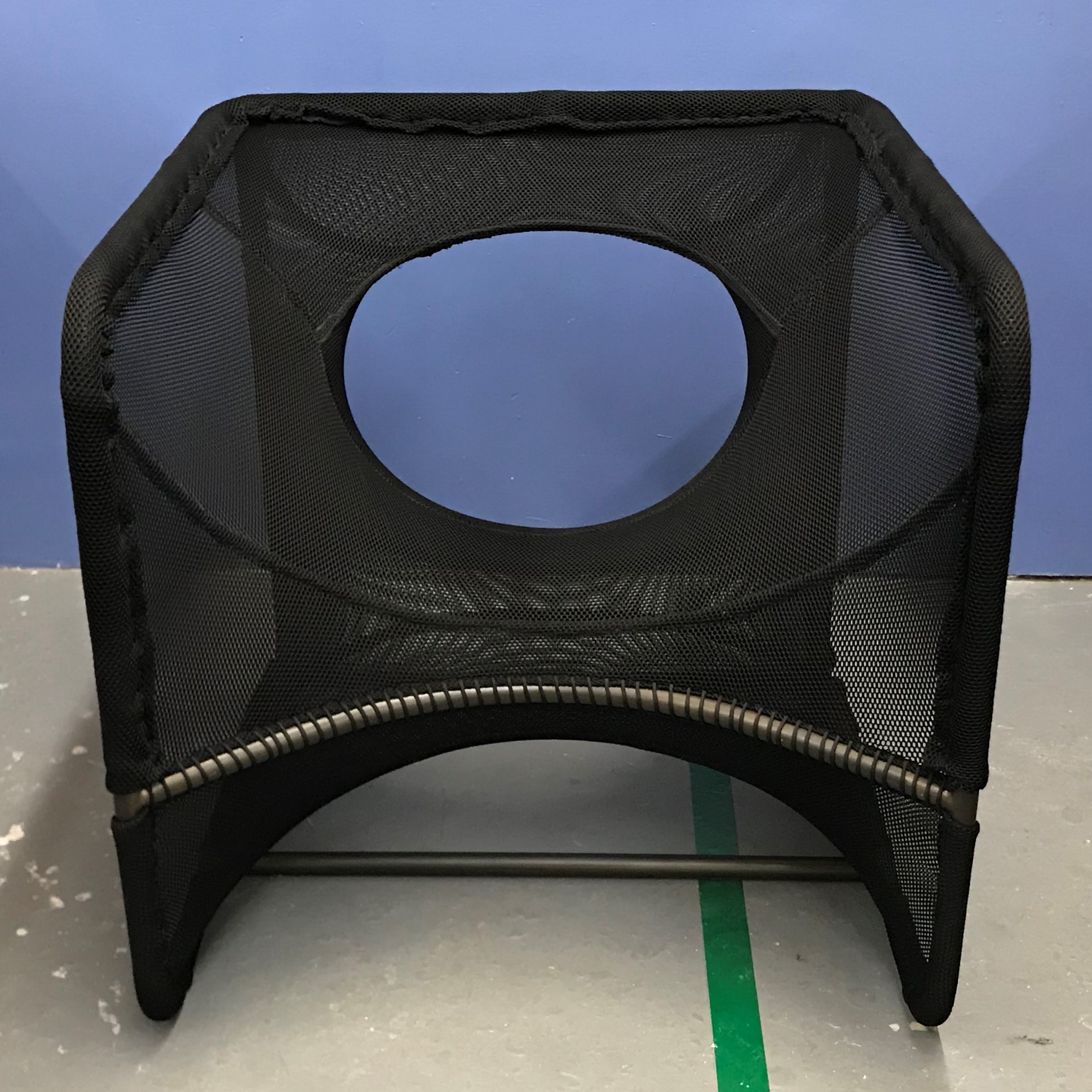

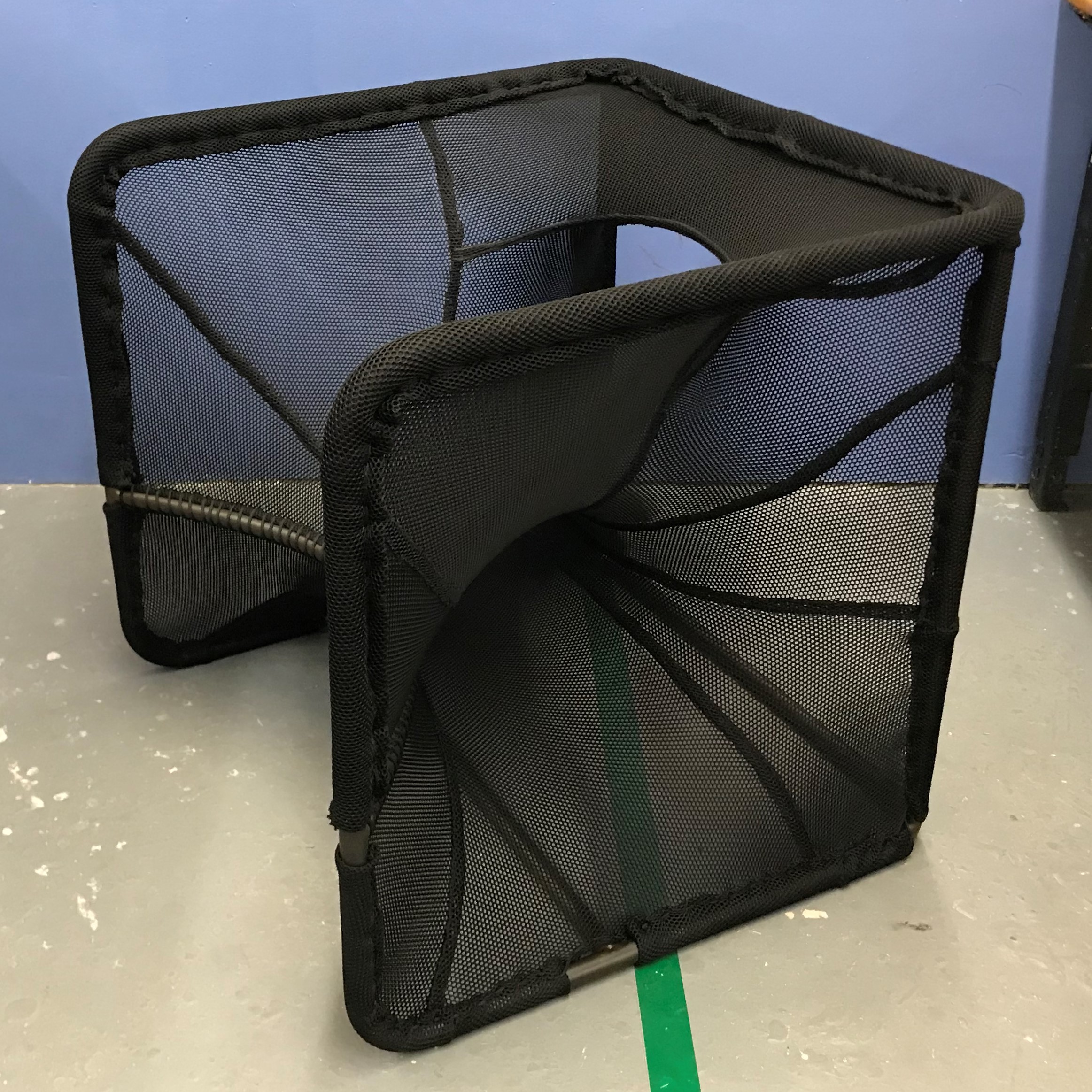

genus chair

concept

“the sculpture is already complete within the marble block, before I start my work. it is already there, i just have to chisel away the superfluous material.”

-michelangelo

just as a sculptor reveals the piece within a block of stone, in this piece i strove to reveal a chair within a cube of air. the seating surface is a purely tensile membrane, pulled to a cubic frame. inspired by the form optimization studies of frei otto, i used digital optimization techniques to generate a minimal surface within my chosen frame.

form finding

through a series of iterations, i attempted to define a chair form using a generated minimal surface within a cubic frame. the form generation was done using the node based programming language grasshopper.

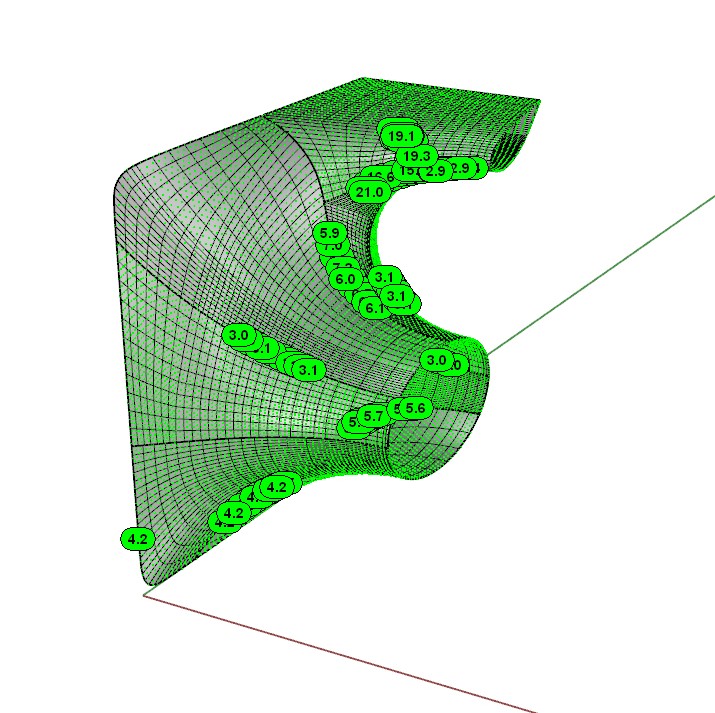

patterning

the surface of my chair is doubly curved. since i will be constructing the textile suspension using a cut and sew technique, i needed to create a set of patterns that will stretch into the final shape, taking into account the stretch characteristics of the fabric. using several tools in the 3d modeling program rhino, i was able to create a pattern. the green dots and annotations give information about the stretch required to go from flat pattern to curved panel in the final piece.

frame analysis

the tension forces on the chair are quite high. coupled with this, i wanted the frame to be as light as possible. to achieve both goals, i decided to build the frame from welded chome-moly steel. to spec the tubing size and wall thickness for the frame, i created several FEA simulations for different loading conditions. the distortion of the frame caused by a seated person is very close to the simulated results. distortion not to scale.

construction

i bent the frame using a diacro and welded with a TIG welder. the fabric was sewn with a zigzag stitch to allow the seams to stretch. all seams are flat fell to finish both sides and add strength.